Updates rolling out in January could have drastically reduced the number of Energy Star windows installed.

Willingness to listen to industry concerns has yielded an updated version of Energy Star Version 6.0 requirements that, at one point, had the potential to significantly cut the number of units eligible for the program.

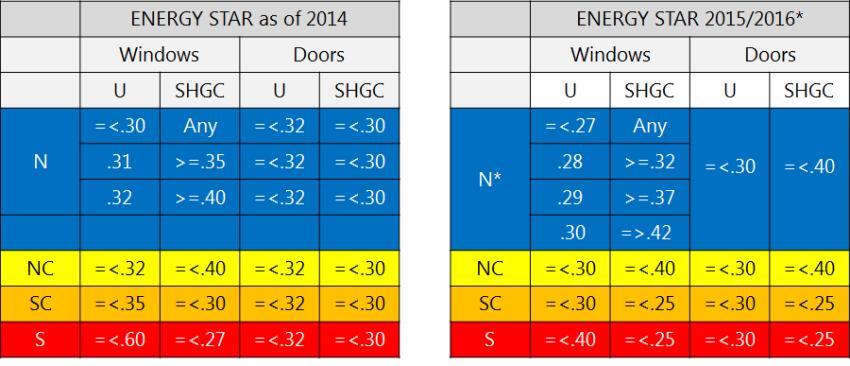

According to the Window and Door Manufacturers Association (WDMA), early drafts of Energy Star Version 6.0, which rolls out in January, put such stringent U-factor and solar heat gain coefficients (SHGC) into effect that it could have resulted in Energy Star products reaching “a market share of less than 50%,” compared with the 80% market share it currently has.

“Especially in the northern zones, which represent such a large area, we were concerned that the cost of the product would become so cost-prohibitive for consumers that they wouldn’t buy Energy Star products, and they wouldn’t have anywhere to turn,” explains Jeff Inks, vice president of code and regulatory affairs for WDMA. Generally, he says WDMA and the industry are “supportive of where the requirements are now.” In back-and-forth discussions with the Environmental Protection Agency (EPA), WDMA asked for substantiation of data the agency used to support U-factor and SHGC changes to determine that the new values would be cost-effective within the timeframe allotted for manufacturers to meet the new criteria.

“We’re at a point now where products and homes are becoming so efficient that we’re really pushing the limits,” Inks says. “Not the limits of where the technology can go, but of how quickly we can get there. It takes time.” To address concerns, EPA ultimately adjusted the implementation date for the northern zone by a full year to January 1, 2016. The U-factor called for the North Central region was also increased to 0.3 rather than 0.29.

Manufacturer Response

Despite frustrations with the process, manufacturers say they’re prepared to meet the timeline for Version 6.0, even without the two-phase roll-out.

Both Marvin Windows and Milgard report that their product lines have been updated to the point where the brands will be able to meet northern 2016 criteria at the time of the 2015 roll-out for the three other regions. Pella also says the vast majority of their product lines will be Energy Star compliant.

“We’re continually looking for ways to improve the energy efficiency of our products to make cost effective sense for our customers,” says Kevin Gaul, acting director of industry and regulatory affairs for Pella. “This is a process that has played out over a number of years, and we continue to make design changes for a lot of reasons, energy efficiency being one of them. Some product lines have very little or nothing to change to reach the new criteria, while others did take some level of effort.”

Representatives from Pella and Marvin say glazing options make the difference in many cases when it comes to achieving a given energy standard, whether that be Energy Star or another program. At Milgard, some changes to frame materials and the addition of foam inserts helped product lines meet goals.

Across the board, manufacturers say they’re working closely with their dealers, builders, and homeowners down the line, to make product selection easier. Online tools have been among the easiest avenues for illustrating which models in a manufacturer’s product line fit the bill for achieving a given energy standard.

“We have all the data in our quote system so our dealers know if a product doesn’t qualify,” says Christine Marvin, director of marketing Marvin Windows & Doors. “We also make sure to leverage the website and have performance data and a series of webcasts and webinars available to continue to reinforce and provide education on the topic.”

Taking advantage of that type of information will be useful to builders no matter what code they’re building to. “Homeowners in today’s day and age are much more aware of energy efficiency than they were 10 years ago,” Gaul says. “It’s a key criteria, expectation, or question they’ll ask, but that’s not the exclusive one.”

Marvin agrees. “There’s such a focus on Energy Star or high-efficiency products, so the industry builds windows and offers glazing options to help satisfy that baseline expectation,” she says. “Without question, energy efficiency is important, but once a window meets that criteria, the buyers will find other aspects of the design style that will help them bring their project to life.”