Types Of Siding and Decking Wood Defects

There has been a recent appearance of many manufactured and composite siding and decking material products on the market. Yet, there are many who still contend that natural wood siding or decking is superior in looks, workability, and finish.

But there are perennial issues with natural wood that must be considered when it comes to your siding or decking.

Nobody’s Perfect!

Because lumber is a by product of a natural process (a tree growing outdoors) it is never perfectly flawless. Unlike manufactured decking material that can be produced to create almost perfect and identical pieces, wood comes with both beauty and flawed characteristics.

So, what do we mean when we talk of “defects” in wood?

The Decks.com website puts it this way,

“Defects in lumber are faults that detract from the appearance and utility of the wood. Some are present when the wood is produced, and others develop or become more severe as the wood ages. As a general rule, you can reduce the number of defects by purchasing higher-grade materials at the outset.”

This is true for any type of wood and for any species. Flaws and defects are inherent in the composition of wood. However, the vast majority of these can be minimal and, in some cases, even add to the look and character of the lumber depending on its end purpose.

Wood Defects: What to Look For

In the industry, there are common terms used to refer to common defects found in lumber. Here is a brief overview:

Checking

Checking also happens with pressure-treated framing materials that are often used underneath decks. Because pressure-treated lumber is usually sold and used while quite green, they are then put under a lot of stress as they dry. This can create checking and the larger pieces such as posts tend to dry out unevenly, which can result in severe checking and splitting.

To the layman, this may be more likely described as cracking, or even splitting in the surface of the wood. Checking describes a crack that runs through a board, most often lengthwise. This typically occurs when lumber is dried too quickly.

Warping

A common sight at lumber yards and big box hardware stores are customers eyeing boards down their length to determine if and how badly they are warped.

Essentially, warping is any bend or twist that varies the true plane surface on a board. Warping happens because of the shrinkage patterns that differ between longitudinal, radial, and tangential directions of a piece of lumber. And warping can the result of growth stresses, which often cause a board to conform to its original shape. Warping can take on a variety of shapes. These include a crook or crown, bow, cup, and twist.

Heart Pith

This is seen as the spongy center of the tree appearing on the surface of a board. This area can become weak as the board fully dries out along with the first three or four growth rings adjacent to the heart pith. These sections can open up and curl at the edges as the board dries.

Knots

A knot in a piece of wood is created where there was a branch. Knots can weaken the board and are often the starting points for checking or cracking. When lumber is graded , any knots are classified by their size, form, soundness and how firmly they are held in place. Lumber with fewer and smaller knots will have higher grades.

What’s Bugging Your Boards?

In addition to defects from improper drying, there are external causes of defects, as well.

Pecking

Mostly found in certain types of wood, such as cypress, pecking is a cavity or pitted area in a board. This is a result of decay caused by a parasitic fungus in the tree. After the tree has been cut, the decay stops but the result is an area of unusually textured board.

Ring Shake

Caused by bacterial parasites that weaken the wood, ring shake appears a cracking between and parallel to the tree’s growth rings. The lumber will typically have less strength and can even come apart. In addition, it can create areas of dark discoloration and an unpleasant odor.

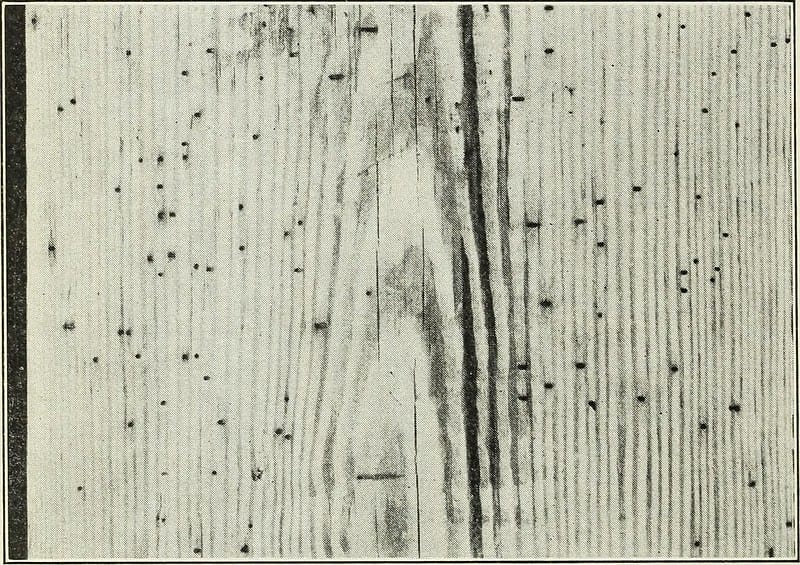

Wood-Boring Holes

Wood-boring insects are known as “secondary invaders” because they are attracted to wood that is already weakened, damaged or dying. The holes left by these insects can mean that the lumber came from a tree in poor health.

Their holes are usually round and are scattered in a random pattern across the wood. These holes can often contain sawdust-like excrement known as frass.

Pitch Pocket

These pockets of bleeding resinous material on boards can happen when a feeding insect damages the living part of the bark. Another cause is the tree being injured prior to being cut down. The residual resin or sap can stain lumber and creating problems with finishing.

Mineral Streaks

Discolored streaks that are sometimes found in boards are commonly called mineral streaks. This occurs after certain minerals in water are drawn into the tree when mold grows on the lumber in poorly ventilated areas. These stains are typically blue or brown in color.

Troubles at the Mill

Wood siding and decking material can also have defects caused when sawing and dressing lumber at a mill. The goal is to reshape a large, uneven log with complex grain patterns and sheared branches, into usable lumber. Because of the machining processes used to produce dimensional lumber, a large amount of stress is applied to the wood, which can result in defects.

Some of the common ones include the following:

- Skip, which is an area where the planer missed the surface, leaving it roughed up.

- Roller check, a crack that occurs when a cupped board is mechanically flattened between roller planes.

- Machine burn, the darkened areas of wood caused by the overheating of the blades.

You can minimize the degree of defects in your wood siding or decking materials by opting for grade one lumber. It is usually better quality wood with greater structural performance than a grade two, for example. Grade two is the most used lumber for posts and the norm for the market. Lumber grading procedures evaluate the various conditions of wood such as species, growing climates and appearance.

As a consumer, you can help ensure quality by properly drying the wood before it is installed. Also, using protective stains on your siding and decking can prevent some later damage to the wood by slowing down the drying process. Using paint or stains can also hide visual defects by providing a consistent color on your siding or deck.